Cold Drawn Lama Products

Uslu Demir Çelik

What are Cold Drawn Lama Products? Where is it used?

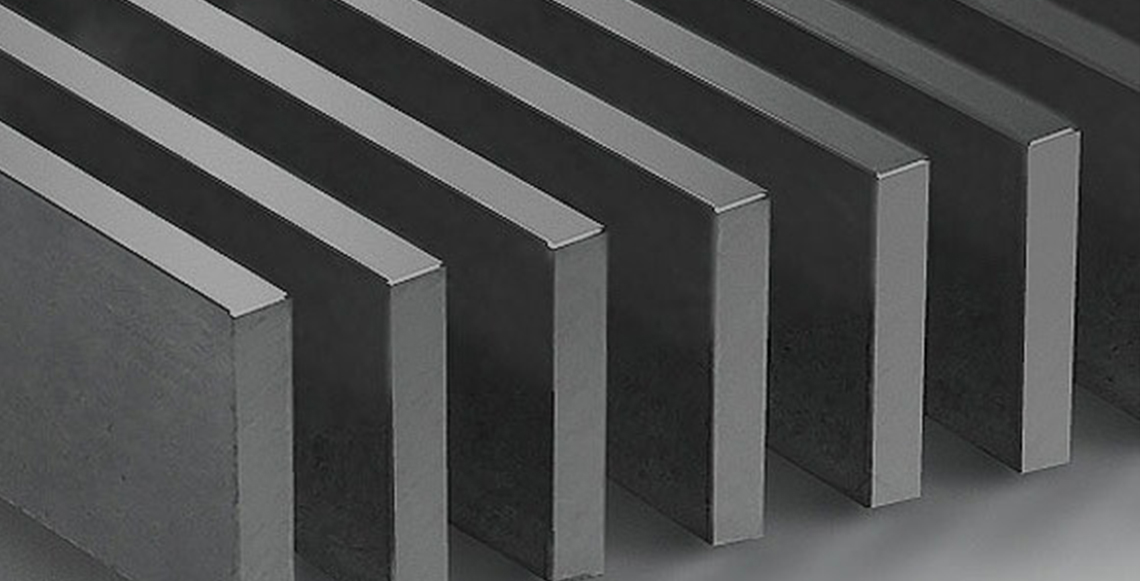

Cold drawn lama products, which have an important place in the iron and steel industry as well as in many business areas, provide many conveniences to the industry where they are used. The product that comes out with the reprocessing of hot rolled iron pieces is called cold drawn lama. With this process, a flexible, durable and extremely smooth iron is produced. Cold-drawn lama products, which made a name for themselves with their durability, are used in many fields of activity due to their high strength values.

Cold Drawn Lama Products

Cold drawn lama products, which have become the favorite of the iron and steel industry, draw attention with their use in many areas. Cold drawn lama products must be produced in an extremely safe and high quality manner with high technology in this sector. Cold-drawn lama products, which draw attention with their strength, are also used extensively in work areas where durability is considered to be the most important characteristic. Therefore it is important to produce high quality and safe cold drawn lama products. Companies that produce cold drawn lama products should purchase these products through businesses that sell these products in a quality way.

Where are Cold Drawn Lama Products Used?

If you are wondering where cold drawn lama products are used, you can continue to read the rest of our article. Cold drawn lama products, which are produced in accordance with EN 10278 standards, are produced as a result of reprocessing the hot rolled iron. The main purpose of this production is to ensure that the products are flexible and durable and also have a smooth structure. These irons, which attract all attention with their durability, are used in various fields of activity. Cold-drawn lama products, which not only strengthen the resistance of the products, but also increase the resistance of the bond between them while combining two profiles with each other, are highly preferred in the business world with these aspects. The main areas where these wonderful products are used are as follows:

* Wrought iron manufacturing,

* White goods production,

* Power transmission lines,

* Agricultural machinery manufacturing,

* Machinery manufacturing,

* Automotive manufacturing,

* Construction of roads, dams and bridges,

* Structural steel sector.

SAMSUN

- Organized industrial Zone Vali Erdoğan Cebeci Blvd. No: 40 Tekkeköy / SAMSUN / TURKEY

- +90 (362) 266 66 21

+90 (362) 266 66 27 - info@usludemircelik.com

ISTANBUL

- Begonya St. No: 3 34746 Ataşehir / ISTANBUL / TURKEY

- +90 (216) 504 82 32

- info@usludemircelik.com

IZMİR

- 35.St. No: 47 Menemen / IZMİR / TURKEY

- +90 (232) 627 92 92

- info@uslucsm.com

OSMANİYE

- E.Ayhan Tosyalı St. No: 7 Toprakkale / OSMANİYE / TURKEY

- +90 (362) 266 66 21

+90 (362) 266 66 27 - info@uslucsm.com